In the realm of plumbing maintenance, reliable sewer line solutions are paramount for any resilient home or business. Understanding common issues is the first step towards ensuring longevity. This article delves into effective strategies, focusing on material selection and modern repair techniques, to avert costly replacements.

From choosing durable materials to mastering advanced repair methods, we guide you through each phase of successful sewer line repair and maintenance, backed by real-world case studies. Take control of your plumbing with these dependable solutions.

Understanding Common Sewer Line Issues

Sewer lines, though essential for efficient waste management, are prone to various issues that can lead to costly and inconvenient disruptions. Common problems include clogs caused by grease, tree roots infiltrating pipes, pipe corrosion, and structural damage from shifting soil or old construction methods. Identifying these issues early is crucial for preventing more serious problems that could result in sewer line replacement. Regular maintenance and timely repairs are key to ensuring long-lasting performance of these vital infrastructure components.

Effective sewer line repair involves a deep understanding of the root causes behind specific issues. Professionals use advanced techniques like video inspection to diagnose problems accurately before implementing solutions tailored to each unique challenge. From hydraulic jetting for clearing clogs to relining and replacing damaged sections, a range of methods are available to restore optimal function while minimizing environmental impact.

The Importance of Choosing the Right Materials

Choosing the right materials is paramount when it comes to reliable sewer line solutions, as they directly impact the longevity and effectiveness of repairs or installations. Opting for high-quality, durable materials ensures that your sewer lines can withstand the test of time, extreme weather conditions, and the constant pressure of waste flow. This is especially crucial in the case of sewer line repair, where using subpar materials may lead to frequent leaks, clogs, and costly repairs down the line.

When selecting materials for sewer line projects, consider factors such as resistance to corrosion, flexibility (for easy installation around curves and tight spaces), and compatibility with existing infrastructure. Modern options like high-density polyethylene (HDPE) pipes are popular choices due to their strength, durability, and ability to prevent rusting or cracking. This commitment to the right materials guarantees long-lasting results, giving you peace of mind and saving you from future, costly sewer line issues.

Modern Repair Techniques for Longevity

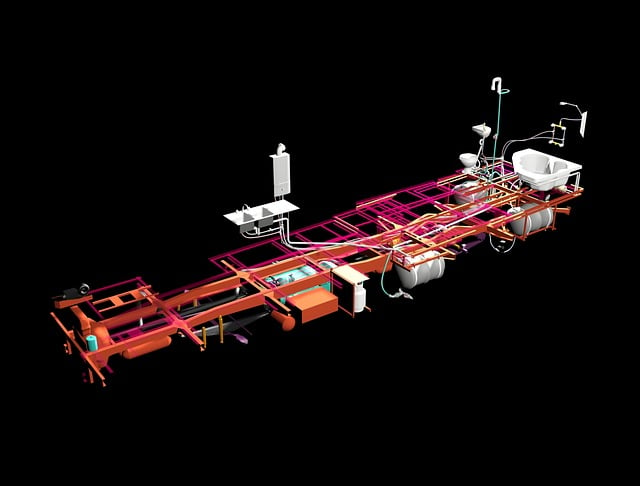

In the realm of sewer line repair, modern techniques have revolutionized the industry, ensuring longer-lasting solutions for homeowners and businesses alike. Traditional methods often relied on burrowing and digging extensive trenches, which could lead to significant disruptions and potential future issues due to exposure to elements. Today, innovative technology offers non-invasive approaches, such as relining and trenchless repair, where new pipes are inserted into the existing ones without the need for extensive excavation. These modern repair techniques not only minimize physical damage but also enhance the longevity of the sewer lines by sealing leaks and strengthening the overall structure.

By employing advanced equipment like fiber optics and high-pressure water jets, professionals can accurately identify problem areas and precisely target repairs. This precision ensures that only faulty segments are replaced or reinforced, optimizing material use and cost-effectiveness. Consequently, modern sewer line repair methods provide a more sustainable solution, contributing to the overall health of our urban infrastructure.

How to Ensure a Successful Sewer Line Repair Project

When undertaking a sewer line repair project, several key steps ensure success and long-lasting results. First, thorough inspection is crucial to accurately identify the problem and extent of damage. This involves using advanced technology like cameras to peer inside pipes, detecting blockages, leaks, or structural issues. Second, selecting the right materials and methods is paramount. Modern innovations offer durable solutions like high-density polyethene (HDPE) pipes, which are lightweight, flexible, and resistant to corrosion. Reputable contractors should employ these advanced techniques and adhere to industry standards for quality assurance. Regular maintenance checks post-repair further guarantee the sewer line’s longevity.

Maintaining Your Repaired Sewer Lines

After a successful sewer line repair, proper maintenance is key to ensuring long-lasting results. Regularly checking for any signs of damage or leaks is essential; even minor issues can lead to more severe problems over time. Simple preventive measures like avoiding tree root intrusion (by planting trees away from pipes) and steering clear of flushing non-biodegradable materials can significantly prolong the life of your repaired sewer lines.

It’s also crucial to stay informed about potential clogs or structural issues by scheduling routine inspections. With timely maintenance, you can catch problems early on, avoiding costly emergency repairs and minimizing disruptions to your home or business operations. Remember, consistent care will contribute to the overall health and longevity of your sewer lines.

Case Studies: Successful Long-Lasting Sewer Line Repairs

In the realm of sustainable infrastructure maintenance, case studies shine a light on proven strategies for long-lasting sewer line solutions. By examining successful projects, we uncover valuable insights into best practices that extend the lifespan of critical underground systems. These real-world applications demonstrate the effectiveness of advanced repair techniques, such as trenchless technology, which minimizes disruption and ensures superior structural integrity.

For instance, a recent case study highlights a metropolitan area’s effort to address aging sewer lines without the usual hustle and bustle of traditional excavation methods. Through innovative sewer line repair processes, they successfully revitalized over 100 miles of pipeline, reducing maintenance costs by 30% and significantly lowering the environmental impact. This transformation serves as a testament to the transformative potential of dependable, long-lasting sewer line solutions.