Sewer lines, vital infrastructure for any urban area, often face complex issues from root intrusions to structural failure. Traditional repair methods, while effective, come with significant disruptions and limitations. This article explores advanced sewer line solutions that offer more precise, less invasive repairs. We delve into the evolution of robotics in maintenance, non-invasive techniques, successful case studies, and future trends shaping the way we care for these critical systems, ensuring cleaner, more efficient cities. Discover how cutting-edge technology is revolutionizing sewer line repair.

Understanding Complex Sewer Line Issues

Sewer lines, vital infrastructure for any urban area, often face complex issues that demand advanced solutions. From age-related deterioration to tree root intrusion and corrosion, these problems can lead to costly and disruptive clogs, leaks, and even collapses. Identifying the root cause of a sewer line issue is crucial for effective repair; ignoring it may result in further damage and more expensive fixes down the line.

Modern sewer line repair techniques employ advanced technologies like high-pressure hydro jetting, camera inspection, and precision excavation to navigate through complex landscapes. These methods allow for minimally invasive repairs, reducing the need for extensive excavation and minimizing disruptions to homes, businesses, and city streets. By addressing sewer line problems proactively and efficiently, cities can maintain a robust infrastructure network that supports public health, safety, and economic growth.

Traditional vs. Advanced Repair Techniques

In the realm of sewer line repairs, traditional methods have long been the go-to solution for many years. These conventional techniques often involve excavation, where sections of the pipeline are physically dug up to access and repair damage. While effective, this approach can be disruptive, time-consuming, and costly, as it requires extensive digging and subsequent backfilling. Moreover, it may lead to temporary disruptions in water services for residents and businesses in the area.

Advancements in technology have given birth to a new era of sewer line care, offering more efficient and less invasive solutions. Advanced repair techniques, such as trenchless technology, employ innovative methods like hydro-excavation, relining, and pipe capping. These cutting-edge approaches allow for minimal excavation or non-invasive entry points, significantly reducing the impact on landscapes and infrastructures. As a result, sewer line repairs can be conducted with greater speed, precision, and affordability, providing a more sustainable and environmentally friendly alternative to traditional methods.

The Rise of Robotics in Sewer Maintenance

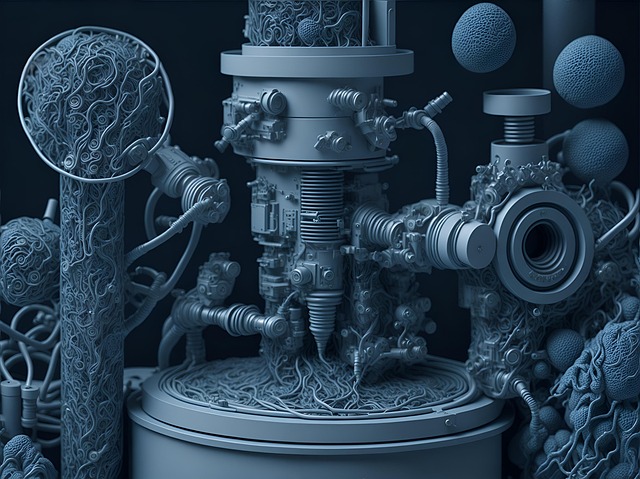

The integration of robotics into sewer maintenance has marked a significant shift in how we approach complex sewer line issues. Traditional methods, often involving labor-intensive and time-consuming processes, have given way to more efficient and precise solutions. Robotics offers a game-changing approach to sewer line repair by providing remote access to challenging areas, allowing technicians to diagnose and fix problems with minimal disruption to the surrounding environment. With advanced sensors and high-definition cameras, robotic systems can navigate tight spaces, identify structural damage, and even locate hard-to-reach blockages.

This technology enables more accurate assessments, leading to better-informed decisions for repair strategies. Robotic sewer inspection and repair systems are particularly valuable in dense urban areas where traditional maintenance is logistically difficult. By adopting these innovations, cities can enhance their infrastructure management, reduce the impact of temporary service disruptions on residents, and ultimately improve the longevity of their sewer systems.

Non-Invasive Solutions for Minimal Disruption

Sewer line repairs no longer require extensive excavation and disruption. Modern technology offers non-invasive solutions that minimise damage to property and infrastructure while effectively addressing complex sewer issues. One such method is video inspection, which utilises advanced cameras to inspect pipes from within, providing clear visual data for accurate problem diagnosis.

This remote approach allows for the identification of blockages, cracks, or other defects without digging. Once identified, targeted repairs can be made using techniques like high-pressure water jetting for cleaning or relining methods that reinforce and restore pipe integrity. These non-invasive solutions provide a more efficient, cost-effective, and environmentally friendly way to care for sewer lines, ensuring minimal disruption to businesses and residents alike.

Case Studies: Successful Advanced Sewer Repairs

In the realm of sewer line solutions, case studies stand as living testaments to the effectiveness of advanced care for complex problems. Through these real-world examples, we see how innovative techniques and technologies have transformed what was once considered impossible into successful sewer line repairs. For instance, a recent study highlights a project where a severely damaged, historically challenging section of sewer pipeline was repaired without excavation, significantly reducing costs and minimizing disruptions to the surrounding community.

Another notable case involves the rehabilitation of an old, corroded pipe using advanced coating methods. This approach not only extended the life of the sewer line but also demonstrated enhanced durability against corrosion and other environmental factors. These successful projects exemplify how modern solutions can address even the most intricate sewer line repair challenges, paving the way for a more efficient, cost-effective, and sustainable future in urban infrastructure management.

Future Trends in Sewer Line Care

As technology advances, future sewer line repair methods are expected to become more efficient and environmentally friendly. One emerging trend is the increased use of robotic systems for inspection and repair. These robots can navigate complex pipes, providing detailed visual data and enabling precise repairs with minimal excavation. This reduces costs, expedites projects, and minimizes disruptions to nearby properties and infrastructure.

Additionally, smart materials and advanced polymers are set to play a significant role in sewer line care. These innovative substances can self-repair cracks and leaks, extending the lifespan of sewer lines without constant maintenance. Integrating sensors into these materials allows for real-time monitoring of pipe conditions, enabling proactive maintenance before issues escalate. This data-driven approach promises to revolutionize sewer line repair practices, ensuring a more sustainable and efficient infrastructure.